| Type:Drying Oven | Condition:New |

| Warranty:1 Year | After-sales Service Provided:Online support, Video technical support, Free Spare Parts, Field installation, commissioning and training, No after-sales service |

| Place of Origin:Henan, China | Voltage:380V |

| Certification:ISO | Dimension(L*W*H):6000*1800*1500mm |

| Power(W):6000 | Application:Medicine Processing, Chemicals Processing, Food Processing, Vegetables,frutis and industrial material |

| Heating source:Electricity | Usage:Dehydrator |

| Installation:We offer | Feature:High quality and low consumption |

| Product Type:As your needs | Drying degree:120 degree |

| Function:Sterilization and dewatering | Temperature range:10 ~200 |

| Delivery:By sea | Weight:5000kg |

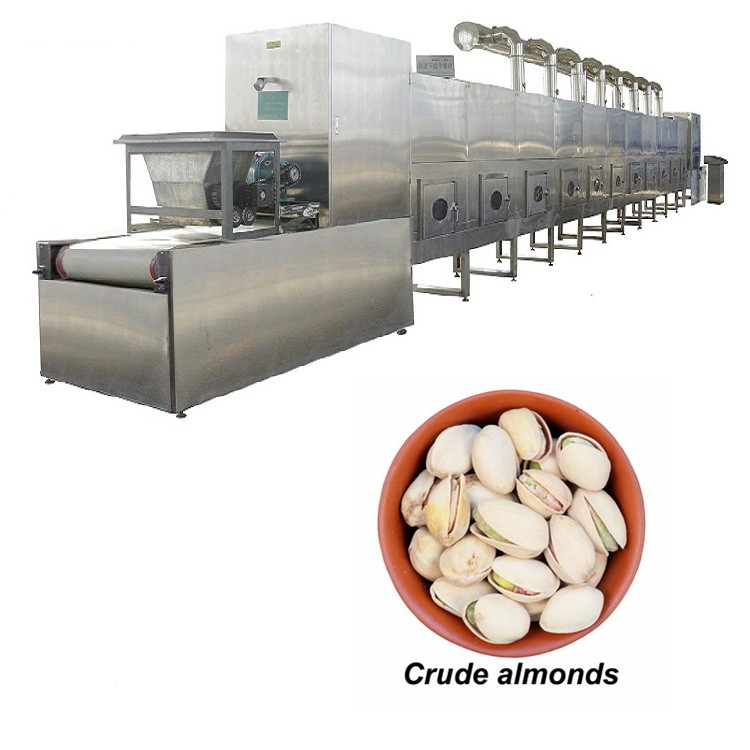

Machine details:

1. Fast heating, It makes heating medium become heater, do not need heat transfer process. Although thermal conductivity is poor materials, also can achieve heating temperature in a very short time.

2. Uniform heating: Microwave infiltrates products uniformly inside and outside to produce thermal energy. So it heats up uniformly and it will not cause problem of burnt outside, but still raw inside.

3. Energy saving: products that contain moisture can be heated easily by absorbing microwave, so there is almost no waste beside a bit in transduction. It is high thermal efficient and energy saving. Compared to infrared radiation heating, it consumes less than 1/3 energy.

4. Sterilizing and freshness preservation: microwave heating can sterilize and be mould proof. Due to fast heating speed and shorting heating time, it well preserves the product’s activity, vitamin in the food, natural color and nutrition.

Features

1.Easily control

The whole machine adopts modular design,and controlled by PLC system, easy operation.

2.Short processing time

Because the microwave has the penetrating property to heat the inside and outside of the material at the same time, no heat transfer medium, so the heating speed is very fast. Typically it will dry materials in one-tenth the time of the standard dryers.

3.Improve final product quality and extend its shelf-life

Microwave has the effect of disinfection and sterilization to keep product safety and extend its shelf-life.

4.Energy savings

The aqueous material easily absorbs microwaves and generates heat, so there is almost no heat loss in the heating process ensure the heating efficiency and energy saving.

5.Uniform heating

The hot air in regular food dehydrators dries foods from the outside. This causes the surface to harden, making it difficult for the water inside to get out and lengthening the drying process. In contrast, the microwave drying machine uses microwaves that reach inside the food, causing the water in it to evaporate. The water vapor is carried away in air currents. This technique results in uniform drying and allows the process to be completed more quickly.

6.Control temperature accurately

The equipment is equipped with the imported infrared thermometer to control temperature accurately, automatically achieve the microwave power adjustment of various materials to meet the microwave energy reach the material inside. The temperature fluctuation range is ≤ 3 °C.

7.Environmental friendly

Microwave drying equipment do not produce "three wastes", because microwave energy is controlled in the heating chamber. There are no radioactive hazards and harmful gas emissions, no residual heat and dust pollution,environmental friendly.

Applications:

1.Chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and Tibetan pill,etc.

2.All kinds of teas,herbs, flowers, green leaves,etc.

3.Various dried meat, like beef, pork, chicken,duck, fish etc.

4. Powder for various material,such as spices, other food additives.

5. Agricultural products,such as china date,nuts,grains,peanut,etc

6.Snack food, fruit seeds, grains, peanuts, chips,etc.

Copyright © 2017 - 2025Shandong Yuansu Mechanical Equipment Manufacturing Co., Ltd. All Rights Reserved