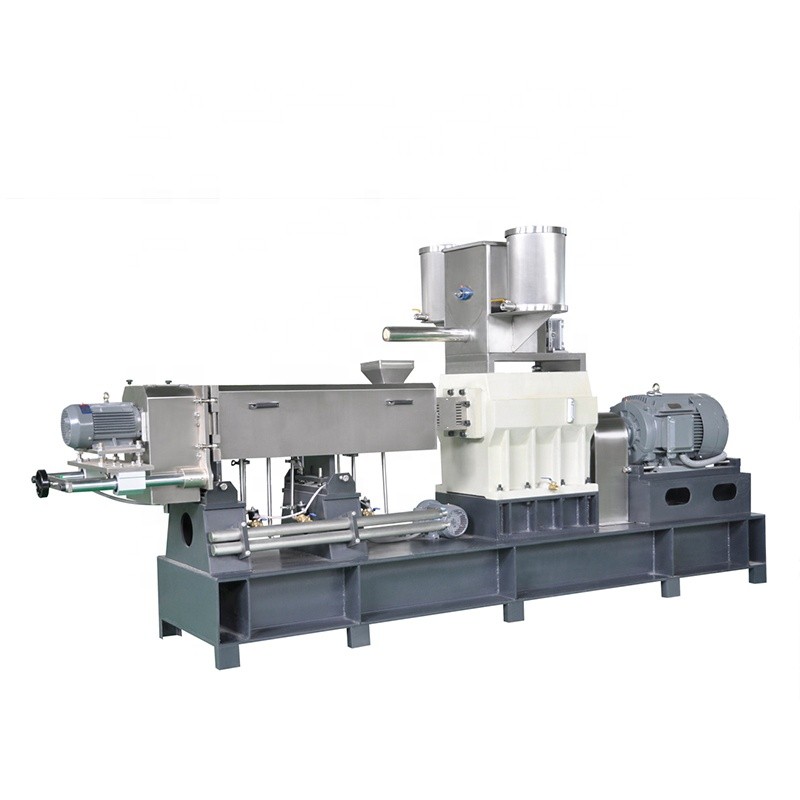

| Condition:New | Warranty:1 Year |

| Place of Origin:Shandong, China | Voltage:Customer's Requirement |

| Application:Good Pet Treats Dog Chews Bone food making Extruder Machine, dog,cat,fish,bird etc pet food | Weight:3000kg, 3-8 tons |

| Certification:CE ISO9001 SGS, CE ISO BV SGS | Dimension(L*W*H):25000*1500*2200 |

| Power(W):80kw | Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Retail |

| After-sales Service Provided:Engineers available to service machinery overseas, Field installation, commissioning and training | Whatsapp:+86 18396800226 |

| fuel:electric,gas,diesel,LPG,steam | After-sales Service:Engineers available to service machinery overseas |

| Capacity:100-1500kg/h | Raw materials:meat meal, fish meal,corn powder, soya meal and other grains powder |

Technical parameter:

| Model | R-126 |

| Capacity | 100kg/hr |

| Hopper volume | 65L |

| Screw diameter | 126mm |

| Power | 22kw |

| Cooling type | Water circulation |

| Heating | No |

| Cylinder pressure | 0.4-0.5Mpa (no more than 0.6Mpa, and cylinder should be changed every 2-3 months) |

| Dimension | 4300*900*2000mm |

Advantage :

1. Alloy (38CrMoAL) screw made by nitriding procedure, high power and wear-resting. Self-cleaning ability, convinient operation with no need to uninstall or clean the barrel and screw when roasting or changing of materials.

2. Implementing speed-adjusted converter on raw material-giving system, extrusion procedure and cutting processing.

3.Food grade stainless steel to keep it clean and no secondary polution ,twin screw feeding device, stable materials feeding in the whole food processing.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. 6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Our Service

In sale service:

24 hours online service .

Configure the machines as your output or request.

Strictly supervise the manufacture of the machines

Convey the manufacture information to you in time.

After sale service:

1 year warranty for the machines.

Overseas installation and train the first-line operators.

For any questions, professional technicians will solve for you timely.

Copyright © 2017 - 2025Shandong Yuansu Mechanical Equipment Manufacturing Co., Ltd. All Rights Reserved