| Condition:New | Warranty:1 Year |

| After-sales Service Provided:Free Spare Parts | Place of Origin:Shandong, China |

| Voltage:380V(customized) | Certification:CE, ISO |

| Application:Frozen food processing | Weight:2000kg |

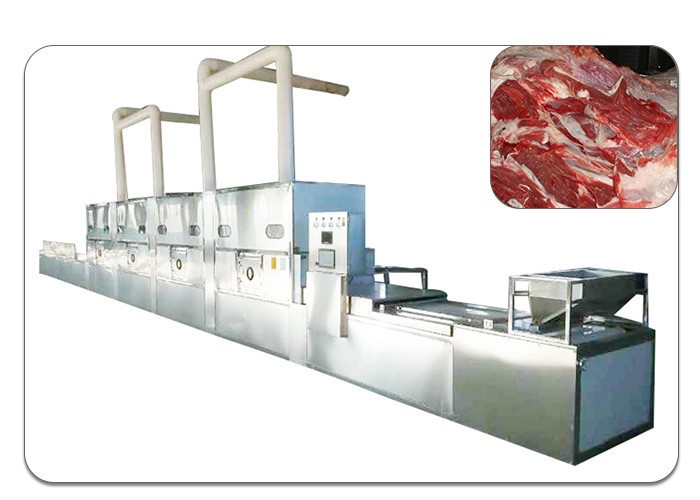

| Automatic Grade:Automatic | Type:Microwave thawing machine, Tunnel type |

| Production Capacity:500~3000 kg/h | Dimension(L*W*H):13000*1000*2000mm |

| Power(W):35~195kw(customized) | Applicable Industries:Hotels, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Food & Beverage Shops |

| Power Source:Electricity | Heating type:Microwave |

| Cooling way:Water/Oil cooling system | Usage:Thawing frozen food |

| Color:Silver | Material:SUS 304 stainless steel |

| Speed of belt:0~10 m/min | Control system:PLC |

Description:

Recirculating Water Thawing Machine pull propeller mainly rely on impetus of big powerful motor and bring hydraulic water wave.The high pressure flowing water thaw the material ,the most natural water flow thawing method,after water circulate to storage water tank with a heated device,that will boost water a few degreed in certain extend while water going through storage water tank,which will acceralating thawing effect.This machine is made of stainless steel which is easy to operate and clean,perform stably and low noisy.

Features:

1.Short time,Quick speed, it does not need the heat conduction.

2.Low temperature sterilization to maintain nutrients and traditional flavor.

3.Saving energy, microwave is a direct action on the food processing, and therefore no additional heat loss.

4.Uniform and thorough, heating inside and outside the material, there is no heat conduction inside and outside temperature difference.

5.Easy to control, the device can be turned on and off, there is no conventional thermal sterilization thermal inertia, without preheating.

6.Simple equipment, advanced technology, small footprint, no other supporting investment, save manpower.

7.Improve the working conditions, save area.

We can provide you the services in the followings:

1. Consultation service before, during, and after sales;

2. Project planning and design services;

3. Installation and commissioning of equipment until everything is functional;

4. Management of equipments' long distance shipping;

5. Training of equipment maintenance and operating personally;

6. New production techniques and formulas;

7. 1 year complete warrantee and life-time maintenance service;

8. Provide English Version of Installation/Operation/Service/Maintenance.

Copyright © 2017 - 2025Shandong Yuansu Mechanical Equipment Manufacturing Co., Ltd. All Rights Reserved