| Warranty:1 Year | After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas |

| Place of Origin:Shandong, China | Dimension(L*W*H):18*0.8*1.6m |

| Power(W):22KW | Weight:4000KG |

| Certification:CE | Voltage:220V 380V |

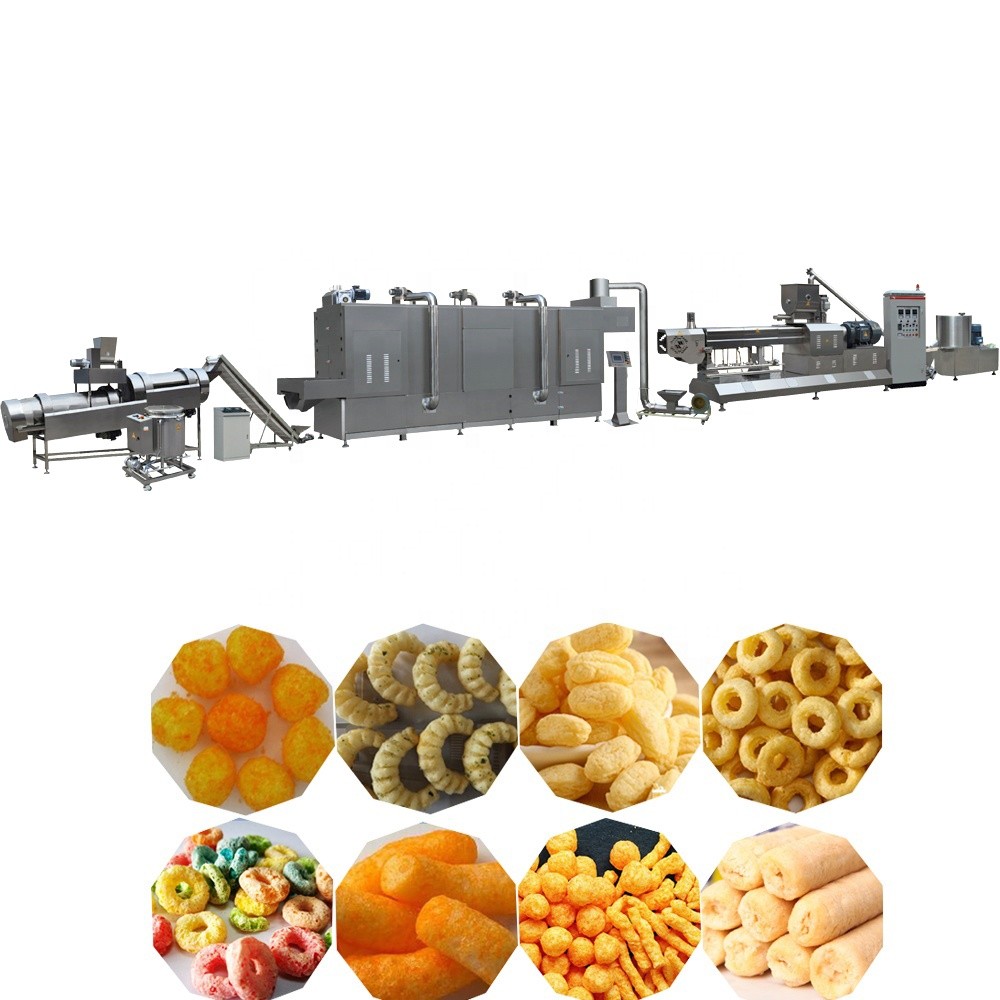

| Applicable Industries:Food & Beverage Factory | Product name:Corn puff snack extruder snacks making machine / production line |

| Keyword:corn puff snack extruder | Main machines:Twin screw extruder, Dryer, Seasoning machine |

| Applictation of snacks making machine:various market popular puffed snacks | Material of food:corn flour,rice flour,wheat flour and so on |

| Factory of snacks making machine:we are factory with more than 20 years history | Processing Types:advance extursion system |

| Advantage of snacks making machine:high quality,advance technology | Material of snacks making machine:food grade stainless steel |

Brief Introduction

1. Small volume,easy operation and high economic

2. Can change the shapes of mould

3. Make corn and rice into various shapes

4.Using corn, millet, broomcorn as raw material, and changing the shapes of moulds, this series of bulking machine can make grain into various shapes of leisure puffing food, such as hollow, clavate, round, spherical, spring type and etc.

Features :

1. Alloy screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Service & Customers

Before sale services:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients’factory.

3.Inspect the machine before leaving the factory.

After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and training. The client need provide room, food, round-trip transportation, visa fee and a nominal daily subsidy per person.

Copyright © 2017 - 2025Shandong Yuansu Mechanical Equipment Manufacturing Co., Ltd. All Rights Reserved